Turn manual assembly into transparent data

AI-powered video analysis reveals where time is lost, which workflows are most efficient, and where quality issues originate.

AI-powered video analysis

Computer Vision for Manual Assembly Processes

AI-powered video analysis

Computer Vision for Manual Assembly Processes

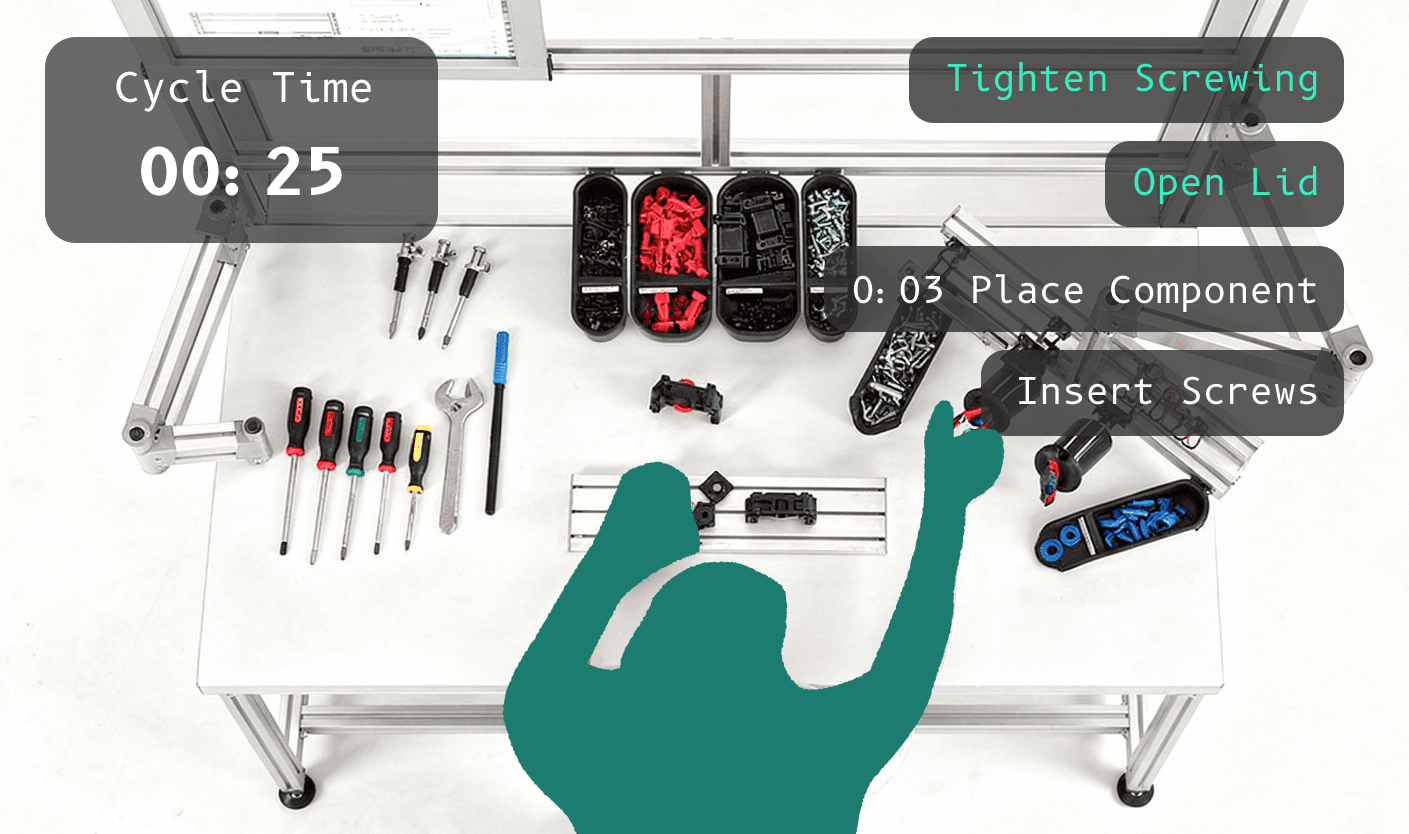

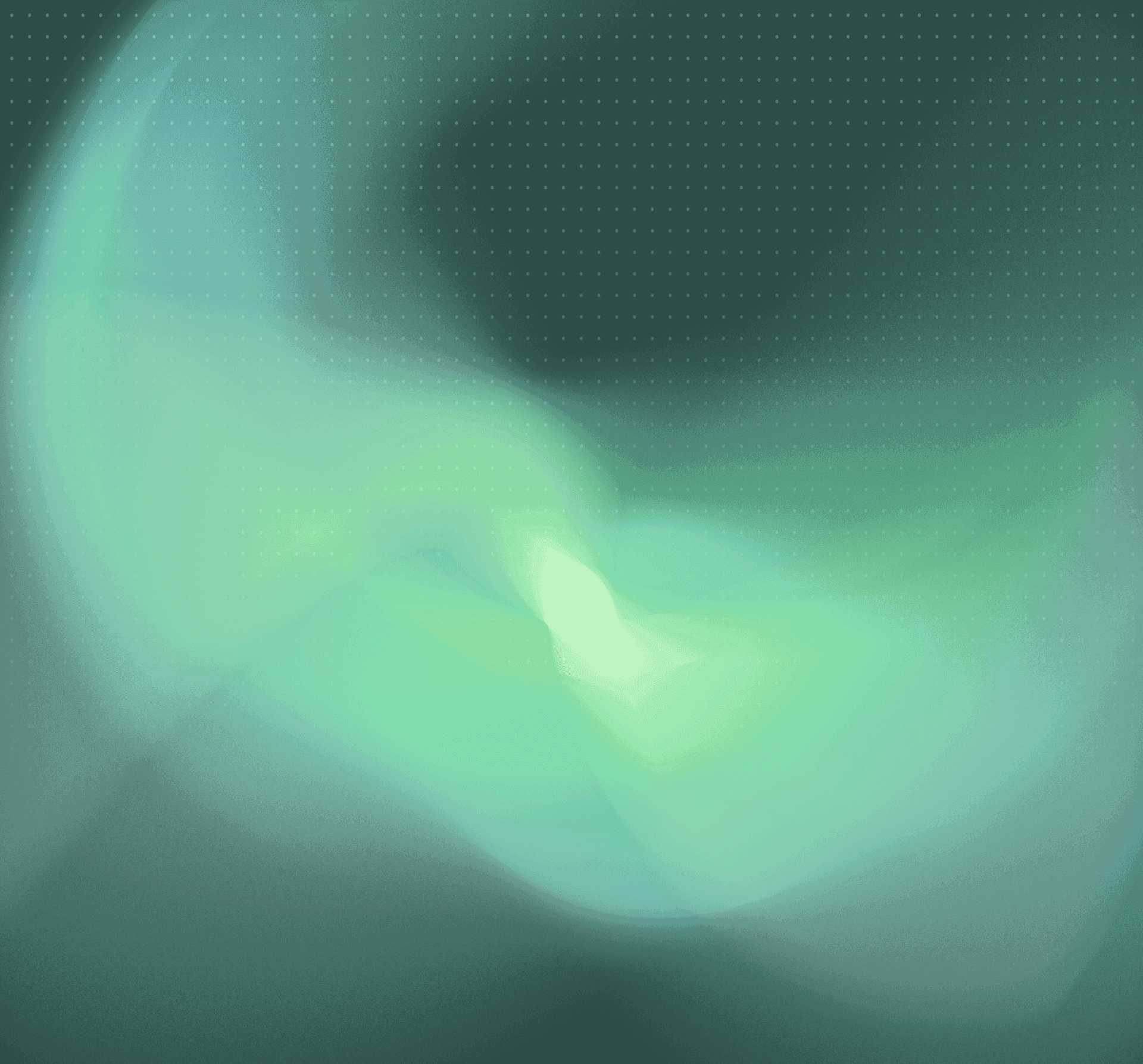

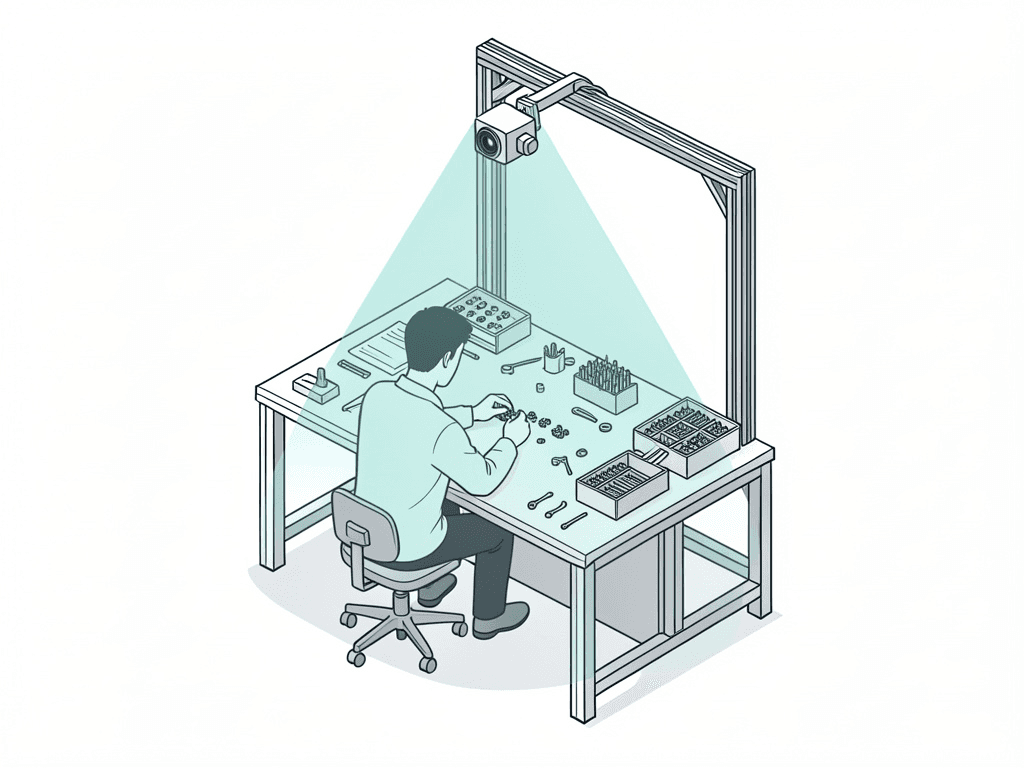

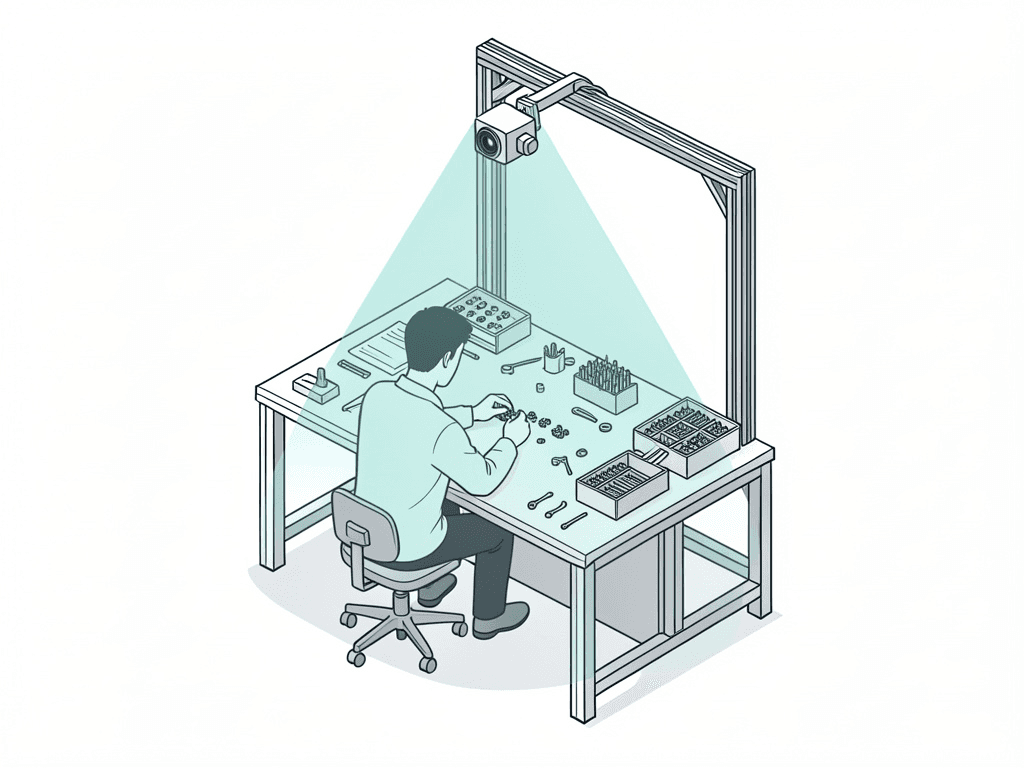

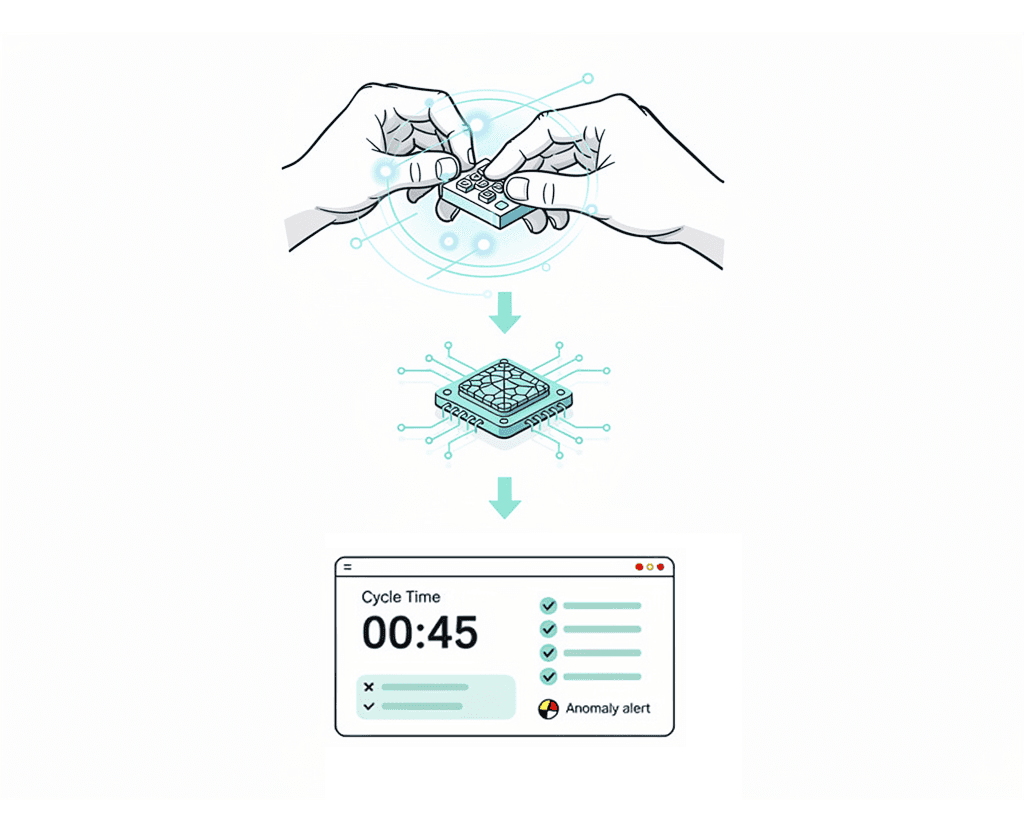

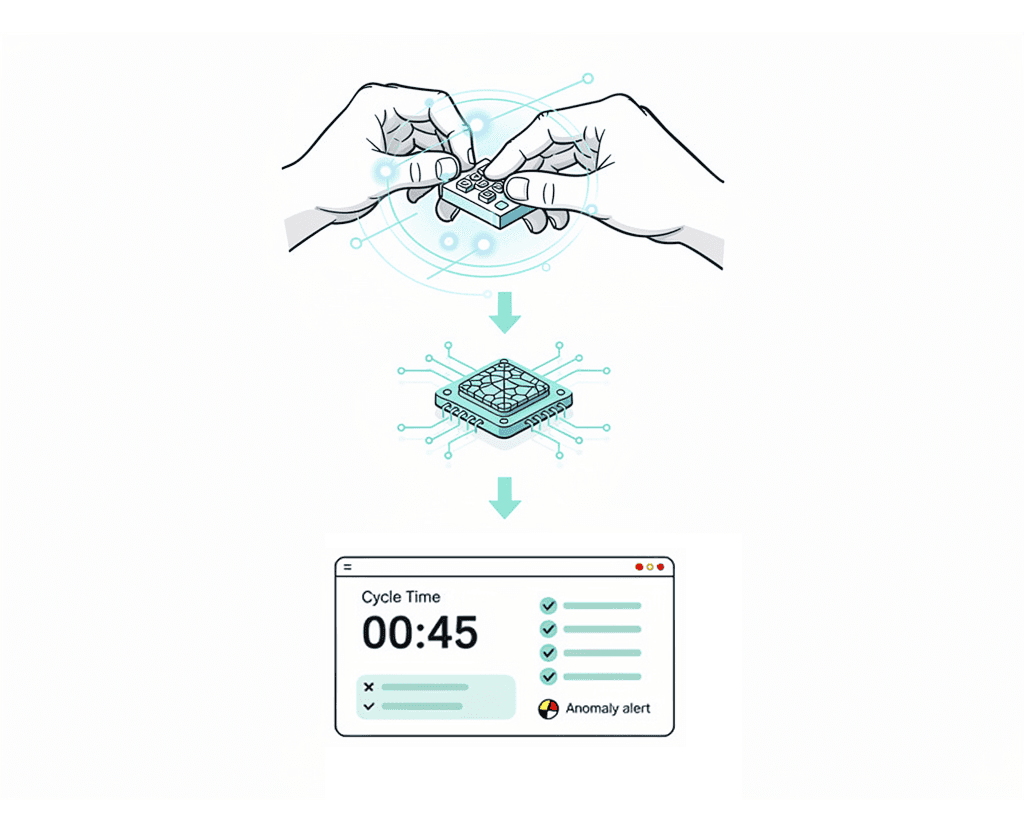

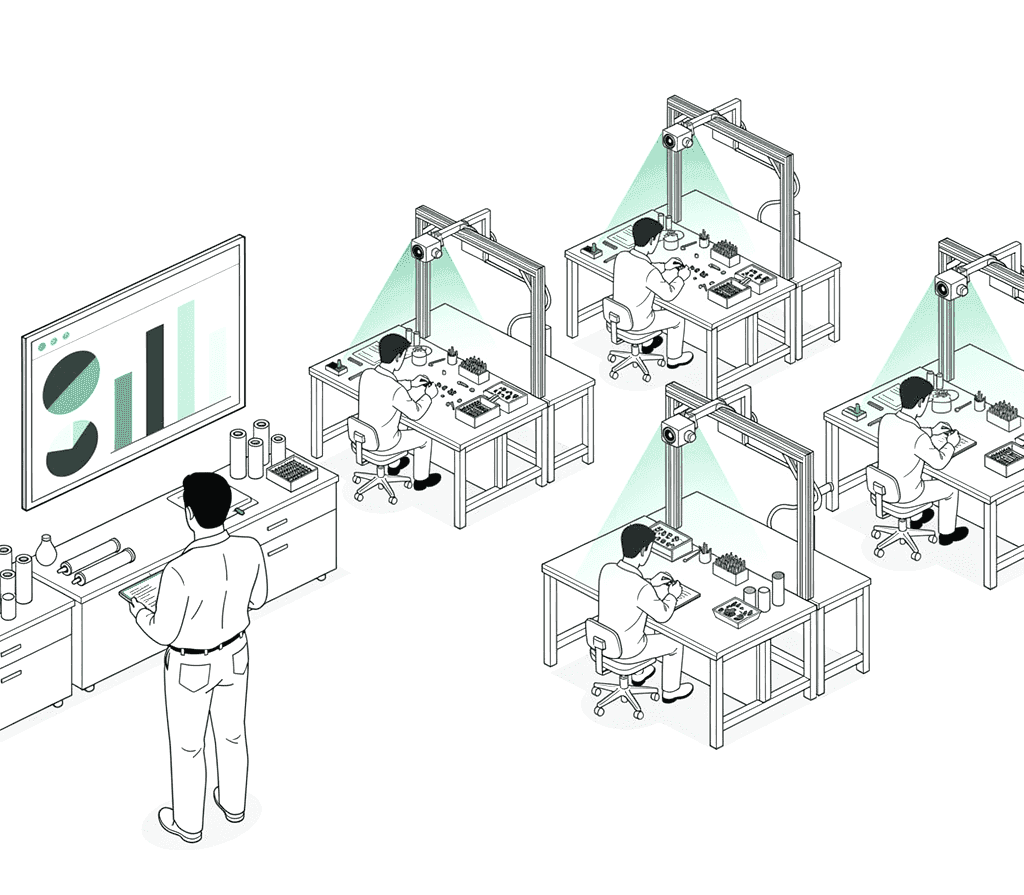

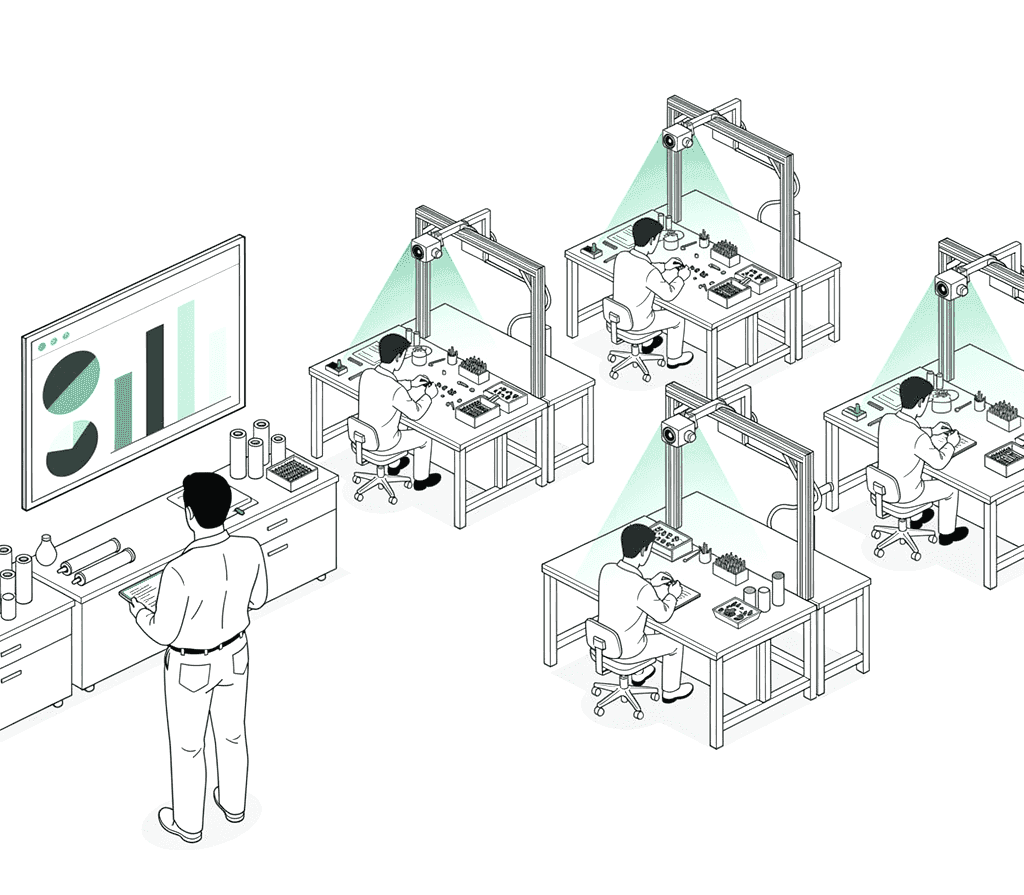

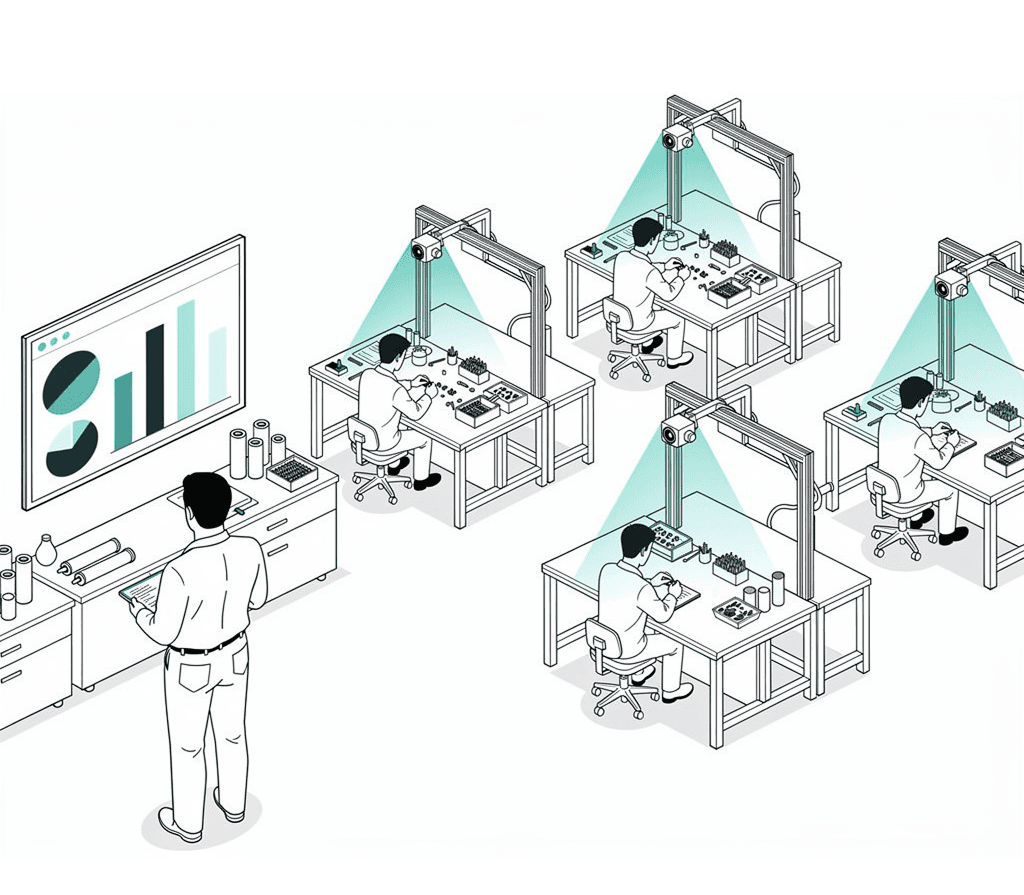

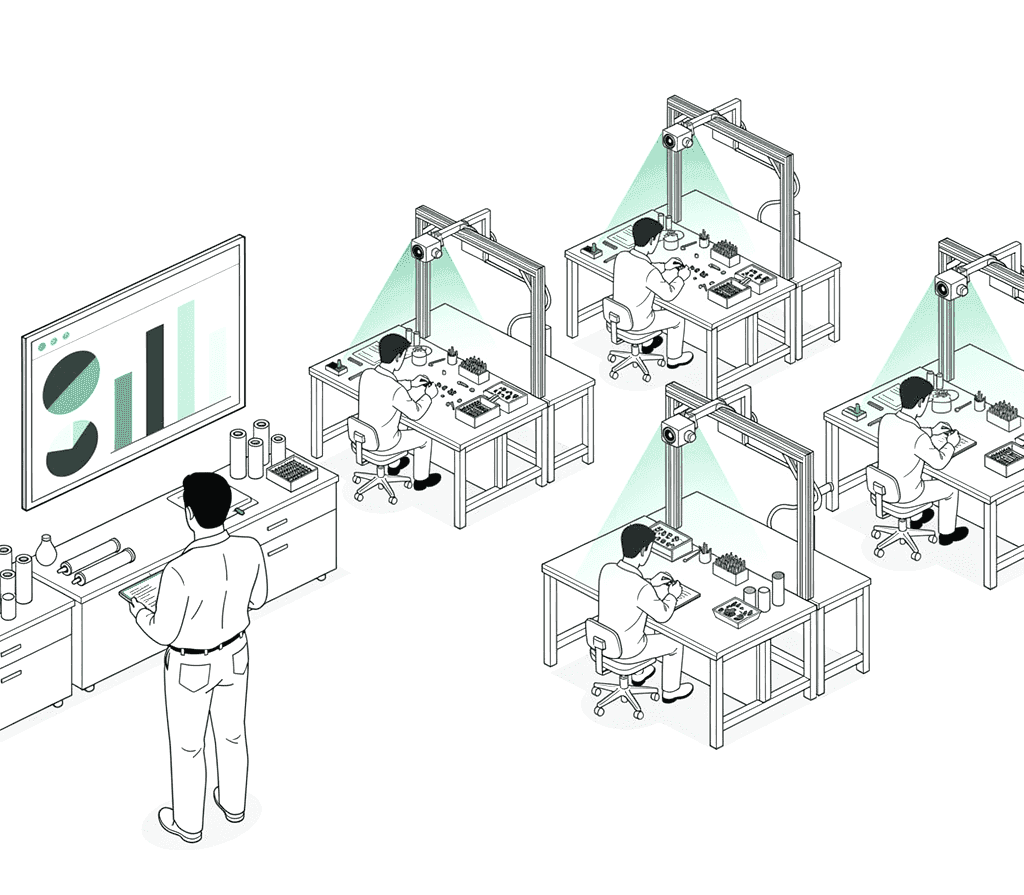

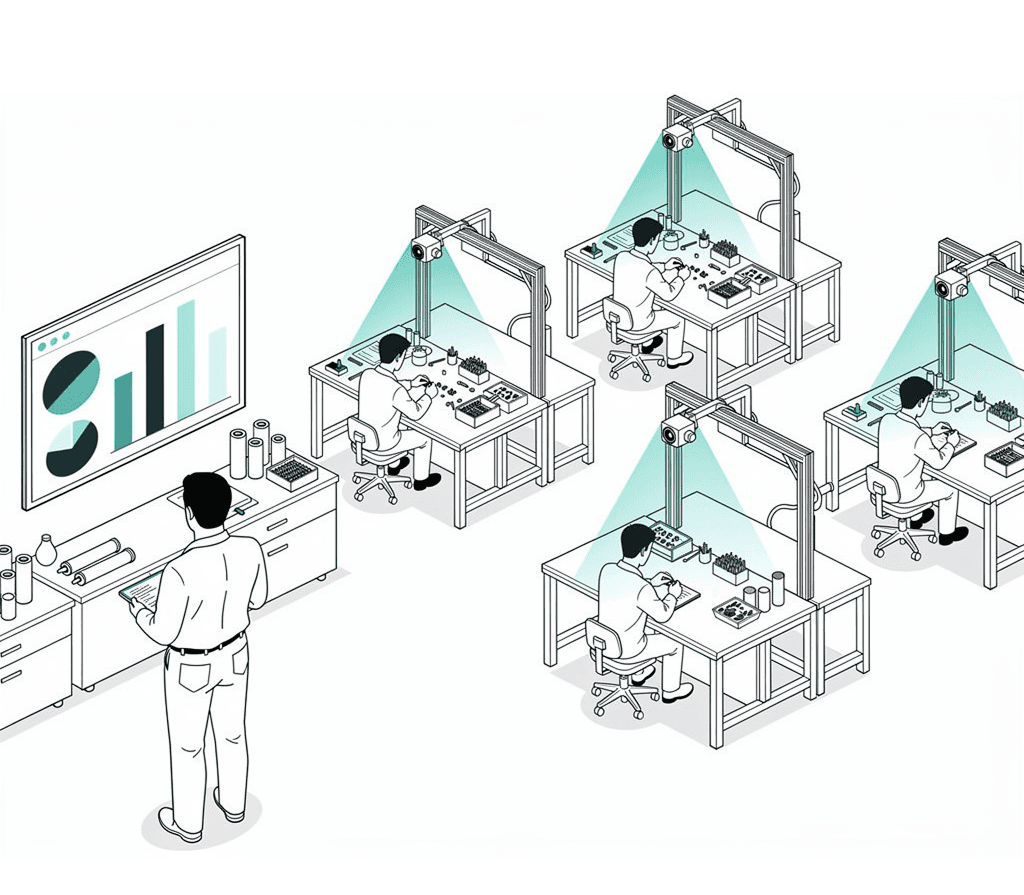

Camera-based Capture

Real-time data from workstations

Cameras mounted above workstations continuously capture every assembly cycle, generating thousands of data points per minute. Installation takes 1-2 days with minimal disruption to production.

Fully anonymized

Fully anonymized

Easy Setup

Easy Setup

No Time Stamp

No Time Stamp

No Maintenance

No Maintenance

Camera-based Capture

Real-time data from workstations

Cameras mounted above workstations continuously capture every assembly cycle, generating thousands of data points per minute. Installation takes 1-2 days with minimal disruption to production.

Fully anonymized

Easy Setup

No Time Stamp

No Maintenance

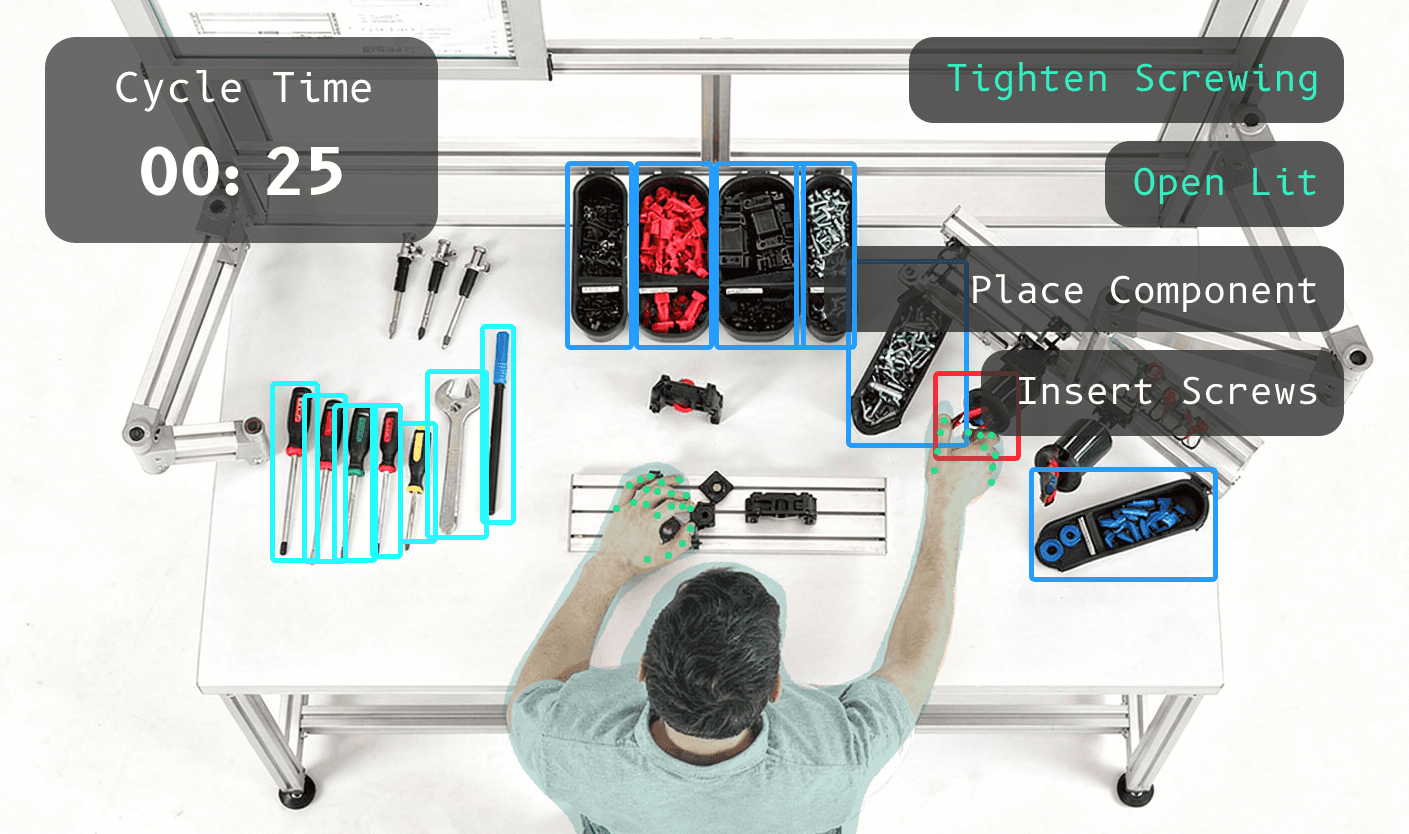

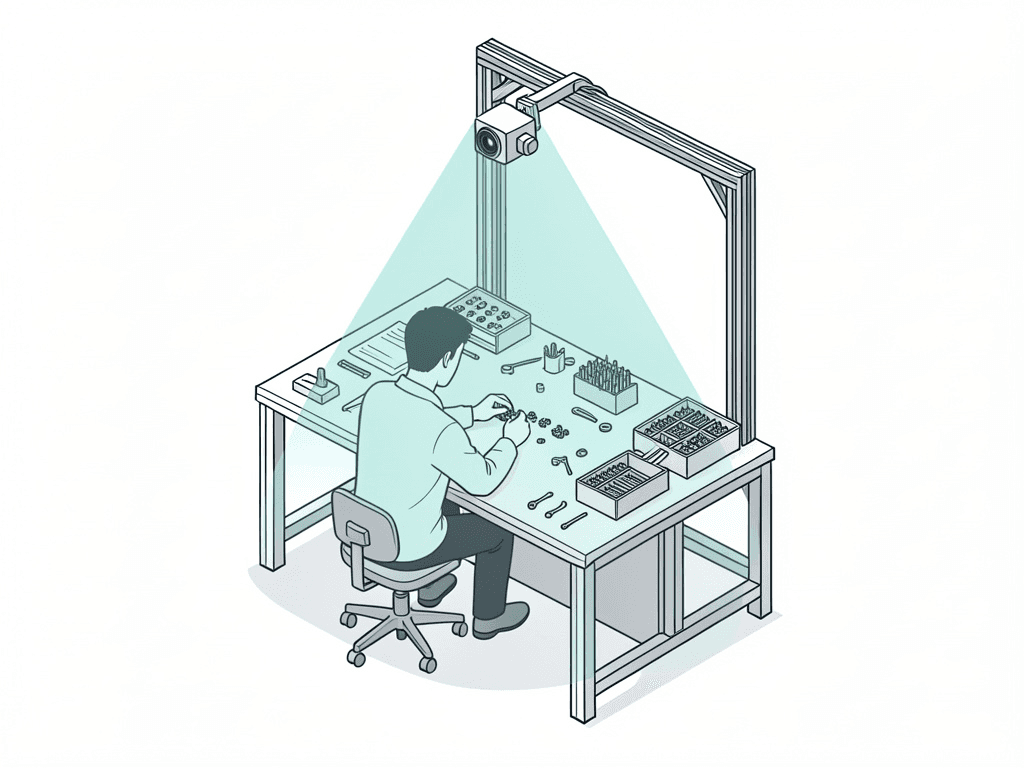

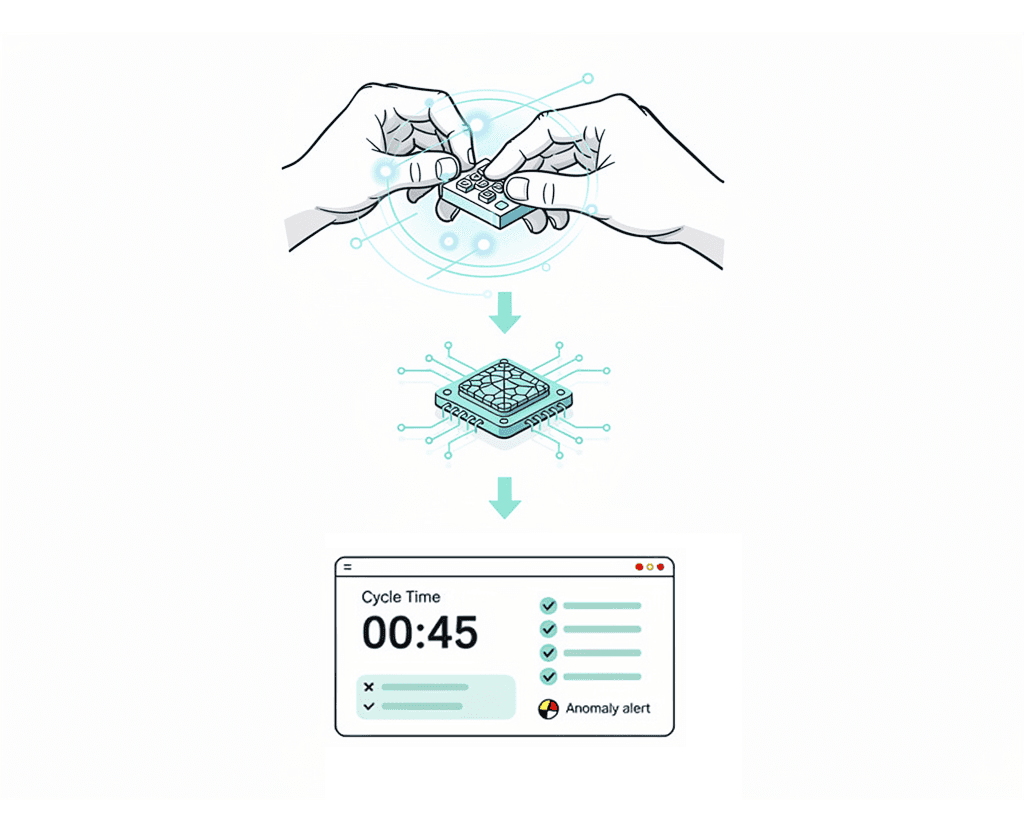

AI Process Analysis

AI detects work steps, cycle times & deviations

The system tracks hands and tools in real-time, automatically measures cycle times, identifies completed work steps, and flags deviations from standard sequences—generating insights without manual data entry.

Fully anonymized

Fully anonymized

Action Detection

Action Detection

Real-Time

Real-Time

Highly Accurate

Highly Accurate

AI Process Analysis

AI detects work steps, cycle times & deviations

The system tracks hands and tools in real-time, automatically measures cycle times, identifies completed work steps, and flags deviations from standard sequences—generating insights without manual data entry.

Fully anonymized

Action Detection

Real-Time

Highly Accurate

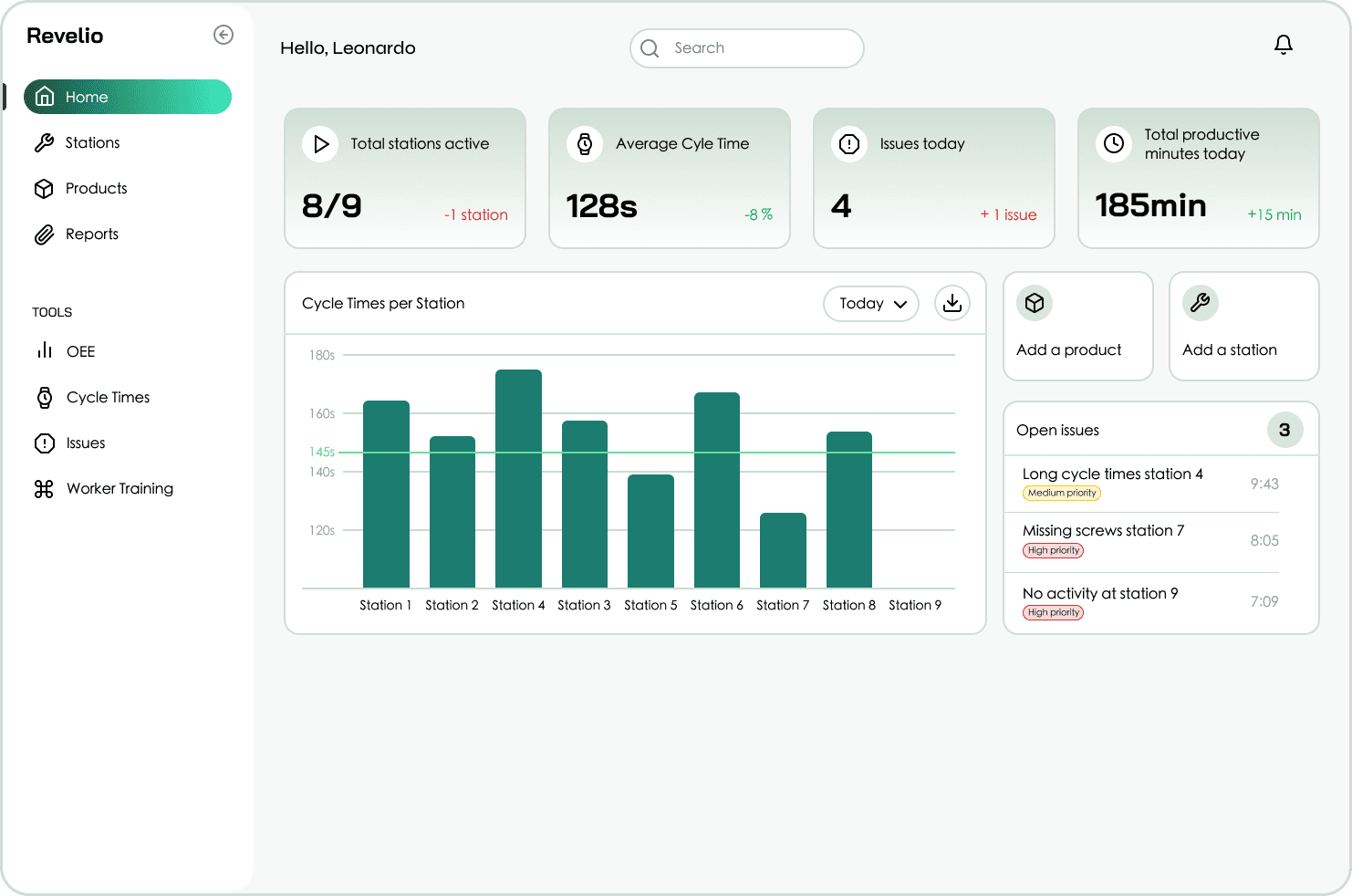

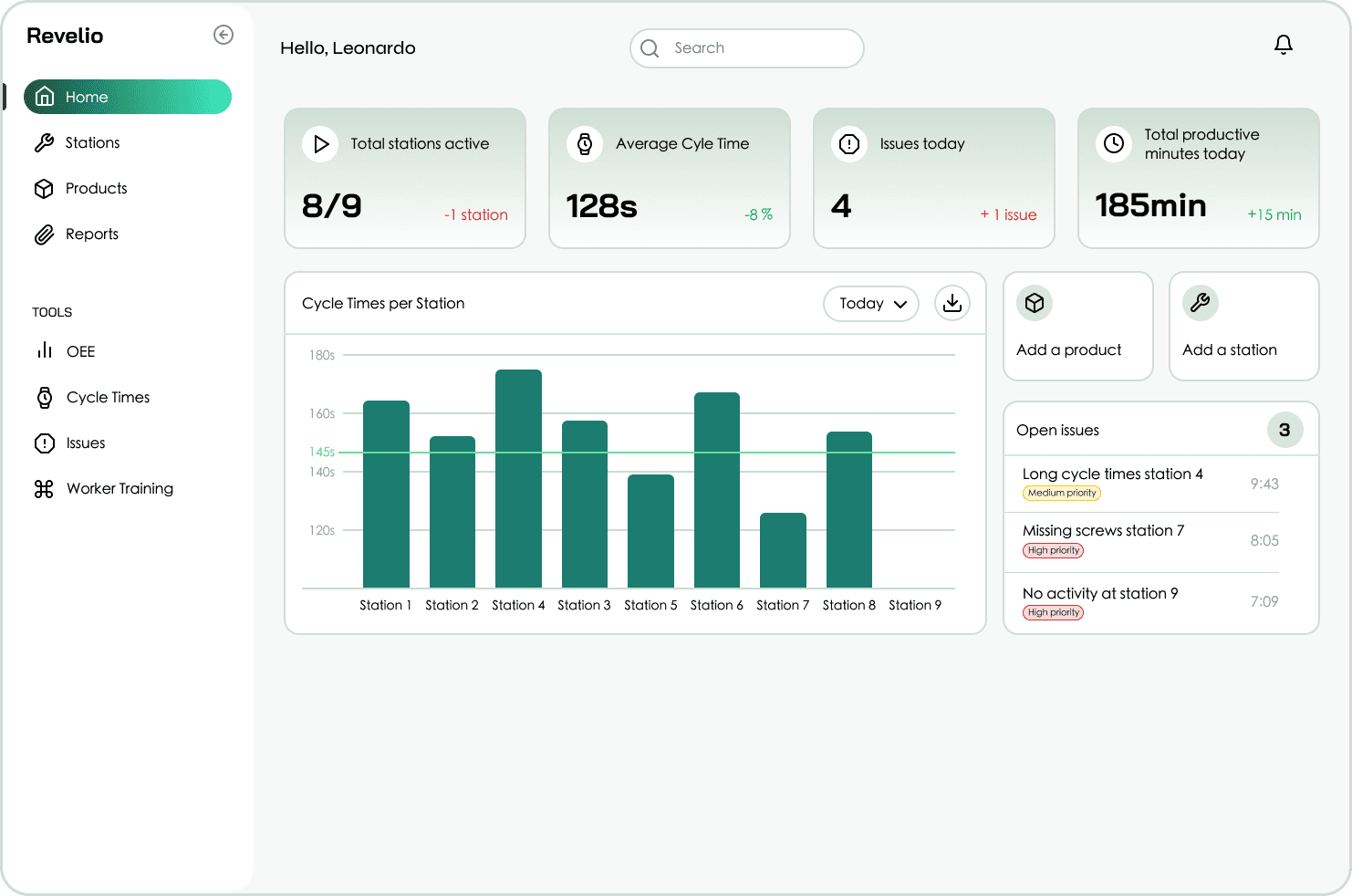

Live Dashboards

Visualize productivity & actionable insights

Real-time dashboards show cycle times, station efficiency, and bottlenecks. See exactly where performance improves and where intervention is needed—all in one view.

Real-Time Alerts

Real-Time Alerts

Cycletime Analysis

Cycletime Analysis

Bottleneck Detection

Bottleneck Detection

Reports

Reports

Live Dashboards

Visualize productivity & actionable insights

Real-time dashboards show cycle times, station efficiency, and bottlenecks. See exactly where performance improves and where intervention is needed—all in one view.

Real-Time Alerts

Cycletime Analysis

Bottleneck Detection

Reports

why it Matters

The hidden cost of manual assembly

MES tracks outputs, not processes

Your MES shows what was produced, not how it was made. Micro-stops, slow cycles, and process variations stay invisible — quietly draining 9-15% of your capacity every day.

MES tracks outputs, not processes

Your MES shows what was produced, not how it was made. Micro-stops, slow cycles, and process variations stay invisible — quietly draining 9-15% of your capacity every day.

Quality issues detected too late

Defects are caught after assembly when rework costs most. Skipped steps, improper sequences, and operator deviations go unnoticed until parts fail inspection—creating costly scrap and delays.

Quality issues detected too late

Defects are caught after assembly when rework costs most. Skipped steps, improper sequences, and operator deviations go unnoticed until parts fail inspection—creating costly scrap and delays.

No continuous visibility

Time studies give snapshots, manual logging is incomplete. Everyday insights at each station are missing.

No continuous visibility

Time studies give snapshots, manual logging is incomplete. Everyday insights at each station are missing.

Root causes stay hidden

You see problems but not their source—which station, shift, or step created the issue remains unclear.

Root causes stay hidden

You see problems but not their source—which station, shift, or step created the issue remains unclear.

Constant firefighting

Without cycle-level data, you react to problems after they've compounded instead of catching them early.

Constant firefighting

Without cycle-level data, you react to problems after they've compounded instead of catching them early.

why it Matters

The hidden cost of manual assembly

MES tracks outputs, not processes

Your MES shows what was produced, not how it was made. Micro-stops, slow cycles, and process variations stay invisible — quietly draining 9-15% of your capacity every day.

Quality issues detected too late

Defects are caught after assembly when rework costs most. Skipped steps, improper sequences, and operator deviations go unnoticed until parts fail inspection—creating costly scrap and delays.

No continuous visibility

Time studies give snapshots, manual logging is incomplete. Everyday insights at each station are missing.

Root causes stay hidden

You see problems but not their source—which station, shift, or step created the issue remains unclear.

Constant firefighting

Without cycle-level data, you react to problems after they've compounded instead of catching them early.

The Team

"Manual assembly has always been a black box. We're giving production managers the same real-time visibility for manual work that they already have for automated processes."

Jan-Philipp Thiele

Co-Founder

"Every factory measures downtime and output, but nobody tracks the hundreds of micro-inefficiencies in manual work. That's where up to 30% of throughput is lost. We're making the invisible visible."

Friedrich Dehn

Co-Founder

"Our vision is simple: every manual workstation should have the same level of process transparency as an automated line. The technology is ready—manufacturing just needs to adopt it."

Tomer Panagiotis Karagiannis

Co-Founder, Lead Developer

"Manual assembly has always been a black box. We're giving production managers the same real-time visibility for manual work that they already have for automated processes."

Jan-Philipp Thiele

Co-Founder

"Our vision is simple: every manual workstation should have the same level of process transparency as an automated line. The technology is ready—manufacturing just needs to adopt it."

Tomer Panagiotis Karagiannis

Project Manager, Google

"Every factory measures downtime and output, but nobody tracks the hundreds of micro-inefficiencies in manual work. That's where up to 30% of throughput is lost. We're making the invisible visible."

Friedrich Dehn

Co-Founder

The Team

"Manual assembly has always been a black box. We're giving production managers the same real-time visibility for manual work that they already have for automated processes."

Jan-Philipp Thiele

Co-Founder

"Every factory measures downtime and output, but nobody tracks the hundreds of micro-inefficiencies in manual work. That's where up to 30% of throughput is lost. We're making the invisible visible."

Friedrich Dehn

Co-Founder

"Our vision is simple: every manual workstation should have the same level of process transparency as an automated line. The technology is ready—manufacturing just needs to adopt it."

Tomer Panagiotis Karagiannis

Co-Founder, Lead Developer

"Manual assembly has always been a black box. We're giving production managers the same real-time visibility for manual work that they already have for automated processes."

Jan-Philipp Thiele

Co-Founder

"Our vision is simple: every manual workstation should have the same level of process transparency as an automated line. The technology is ready—manufacturing just needs to adopt it."

Tomer Panagiotis Karagiannis

Project Manager, Google

"Every factory measures downtime and output, but nobody tracks the hundreds of micro-inefficiencies in manual work. That's where up to 30% of throughput is lost. We're making the invisible visible."

Friedrich Dehn

Co-Founder